Molecular Motion

Alexei Sokolov, Governor’s Chair in polymer science, is manipulating molecules to create materials with useful characteristics

Electric cars powered by eco-friendly batteries, able to travel over 300 miles without recharging.

Airplanes built with lightweight composite materials stronger and more durable than metal.

A solution that can preserve vital organs for years outside the body for later use to save lives.

Sound like elements of a futuristic science fiction movie? These applications of science are not from The Matrix, Blade Runner, or Avatar. They are becoming reality for Alexei Sokolov, the UT-ORNL Governor’s Chair in polymer science and leader of the Soft Matter Group.

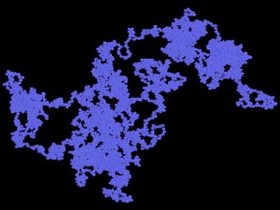

Sokolov’s group focuses primarily on experimental studies into the dynamics of soft materials and molecular biophysics. The research can be divided into four major topics: glass transition and polymer dynamics; dynamics of biological macromolecules; nanocomposite and nanostructured materials; and nano-optics and plasmonics.

“The main goal of our research is to develop a fundamental understanding of molecular motion and its relationship to the macroscopic properties of polymers and other materials,” Sokolov says.

Molecular motion, as the name suggests, is the motion or energy change that occurs in a molecule. According to Sokolov, all synthetic and biological molecules depend on molecular motion. “If molecules don’t move in my body, I am dead,” he explains. “Life is a molecular motion.”

When applied to polymers—large molecules composed of repeating structural units—Sokolov’s work involves fabricating the molecules in an effort to control their properties and create materials with useful characteristics. The term “polymer” is usually associated with plastics, but encompasses a large class of natural and synthetic materials.

One example of the advantage of polymers is their mechanical property. By adding specific nanoparticles to a polymer, Sokolov and his team can create lightweight, polymeric-based composites with greater mechanical strength and toughness than metal and thus significantly improve the fuel efficiency of cars, trucks, and airplanes.“The advantage of polymers is that they have many unique properties we can use by changing their molecular structure and architecture,” Sokolov explains.

Sokolov always wanted to discover something that no one else knew and, since high school, wanted to be a physicist. As a professor of polymer science at the University of Akron, he became interested in glass transition as a general understanding of polymers and became fascinated with molecular motion.

“I realized the potential of polymers 12 years ago,” Sokolov says. “We are trying to answer questions no one else could answer by studying the most fundamental issues of molecular movement. Although it’s far from application, it excites me to unravel phenomena that nobody else understands. The breakthroughs and totally new ideas and technologies are what drive our research.”

The aerospace industry has already begun using polymers in place of metals. Boeing, for example, has created the 787 Dreamliner aircraft that contains 50 percent composite materials in its primary structure, including the fuselage and wings. However, explains Sokolov, the use of such materials in automobiles is not yet feasible. “We are a ways off from replacing the metal in our cars because it is too cost-prohibitive at this point,” he says.

But the batteries in electric cars could be significantly improved by applying the knowledge of molecular motion to polymers. Currently, electric cars only travel between 50 and 90 miles per charge. Rechargeable battery technology uses lithium ions that move between the negative and positive electrodes and back in order to create a charge. This movement occurs within a liquid, which must be contained and adds weight to the battery.

“If we can remove the liquid and use a thin polymer film instead, it will reduce the weight of the battery, remove the big box, and be more environmentally friendly,” Sokolov explains.

“We are probably five to ten years away from this technology becoming a reality,” Sokolov says. “But even then, we will still work on improving the technology.”However, the problem facing Sokolov and his research team is that ions do not move through polymers as fast as they move through liquid. By discovering how the ions are moving, Sokolov can help design the right molecules and chemistry to help ions move as fast as possible.

Understanding the fundamentals of molecular motion also provides the potential to develop a way to preserve proteins over time, a process that can have far-reaching effects on regenerative medicine. Developing technology for re-growing organs and tissues is one of the current problems. The next challenge is to keep the organ or tissue alive. This is also the problem with organ transplants in current medicine.

When a protein is exposed to humid air, it immediately begins to degenerate. For example, when you purchase a piece of meat from the butcher, you have a limited window of time before the meat goes bad. You can put it in the freezer to preserve it longer; but the optimum flavor is gone because biological systems contain water, which crystallizes and destroys cells and tissues.

“We have already developed a solvent that can keep biological molecules active for 10 years,” Sokolov explains. “Now we want to bring this technology to cells, tissues, and organs for transplants.”

The idea is to replace the water in biological systems with another liquid that will not freeze—similar to antifreeze in vehicles. Sokolov’s goal is to find a way to suppress the motion of the proteins, but still allow them to keep their structure. But first, he must understand the molecular motion of proteins.

“It all comes back to that,” he says. “Molecular motion is the key.”

Leave a comment